- +86 135 6079 0959

+86 158 1435 8559 - zhuhuashiye@dgzhuhua.com.cn

0YEAR

Deeply engaged in the field of clean engineering

0+

Technical staff of various types

0+

Purification engineering certification projects

0

Professional Qualifications

ABOUT US

Company Profile

Dongguan Zhuhua Industrial Co., Ltd. is a medium-sized modern service company integrating engineering design, installation, construction, and industrial production process planning. Zhuhua is dedicated to serving various production enterprises, providing one-stop services and solutions for thousands of domestic and international enterprise projects, contributing outstanding strength to enterprises in need!

Our core philosophy

Professional focus

Enriching products

Energy saving and high efficiency

High quality service

2008

Company founded.

2013

Ventured into PGC (Professionally Generated Content) operations, expanding talent pool to over 100 employees.

2016

Established Yancheng subsidiary—Yancheng Zhuhua Environmental Technology Co., Ltd., specializing in decoration, construction, and HVAC purification, with an initial team of 20+ employees.

2017

In 2017, we established an international trade team, formed partnerships with foreign companies including S.P.A Condor Multimedia and Coats Group PLC, and also collaborated with Haier and Midea on refrigeration projects in the same year.

2018-2020

Gained strong recognition and formed deep collaborations with high-tech electronics industrial parks and biopharmaceutical incubation zones in Dongguan (Guangdong), Yancheng (Jiangsu), Huangshi (Hubei), Tongling & Ma'anshan (Anhui), Guiyang High-Tech Zone (Guizhou), and Wenshan (Yunnan). Talent pool expanded to over 100 professionals.

2020-2021

Obtained multiple secondary qualifications and successfully delivered thousands of high-quality domestic and international projects. Earned high praise and long-term partnerships with renowned enterprises such as Lens Technology, Yutong Group, and Jiangsu Yuguan.

2025

In 2025, the company purchased 6,000 square meters of factory premises.

Quality Control

Cleanroom quality assurance is achieved through full - process control in design, construction, equipment, monitoring, and management to ensure the environment meets stringent standards. The core aspects are as follows:

Compliant Design and Construction

Select materials (such as stainless steel and anti - static floors) according to the cleanroom class (e.g., ISO Class 5 - 8). Optimize the airflow layout to eliminate dead zones and minimize dust accumulation.

Control cleanliness throughout the construction process: Workers should wear cleanroom clothing. After completion, perform purging and leak testing. Conduct leak testing on high - efficiency particulate air (HEPA) filters before installation (leakage rate < 0.01%).

Reliable Equipment and Systems

Air - handling equipment is equipped with multi - stage filtration (filtration efficiency ≥ 99.99%). Temperature and humidity control is within ±0.5°C/±2% RH. The air velocity of fan filter units (FFUs) is 0.45m/s ± 20%.

Real - time monitoring: Continuously monitor airborne particles, differential pressure, temperature, and humidity. Automatically alarm and adjust when parameters exceed the standard, and restore normal conditions within 10 minutes.

Standardized Operation and Maintenance

Graded cleaning: Wipe dust daily and disinfect weekly. Use anti - static tools and avoid cotton materials.

Regular maintenance: Replace pre - and medium - efficiency filters based on differential pressure. Replace HEPA filters when the final resistance is at least twice the initial resistance. Conduct third - party testing of 12 indicators annually.

Personnel training: Workers must pass assessments on cleanroom behavior and electrostatic protection. The annual retraining rate should be 100%.

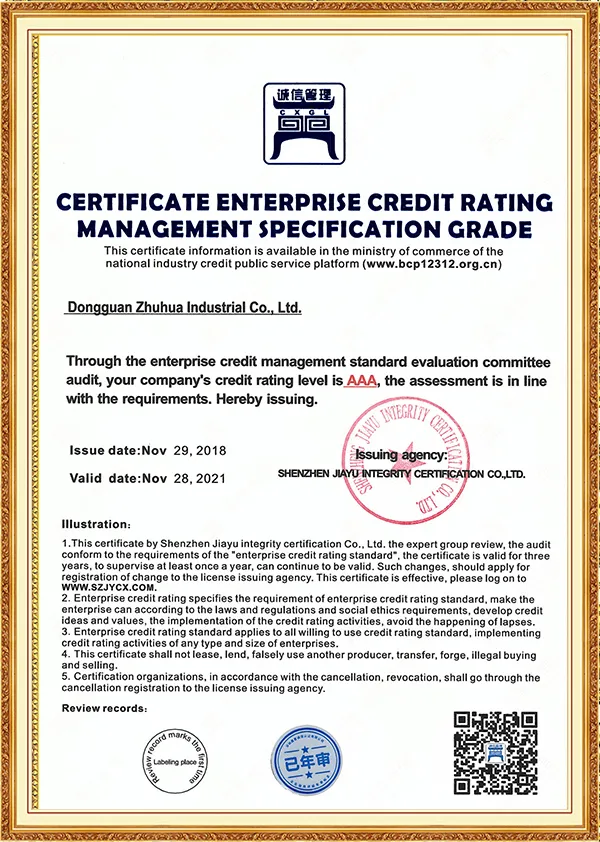

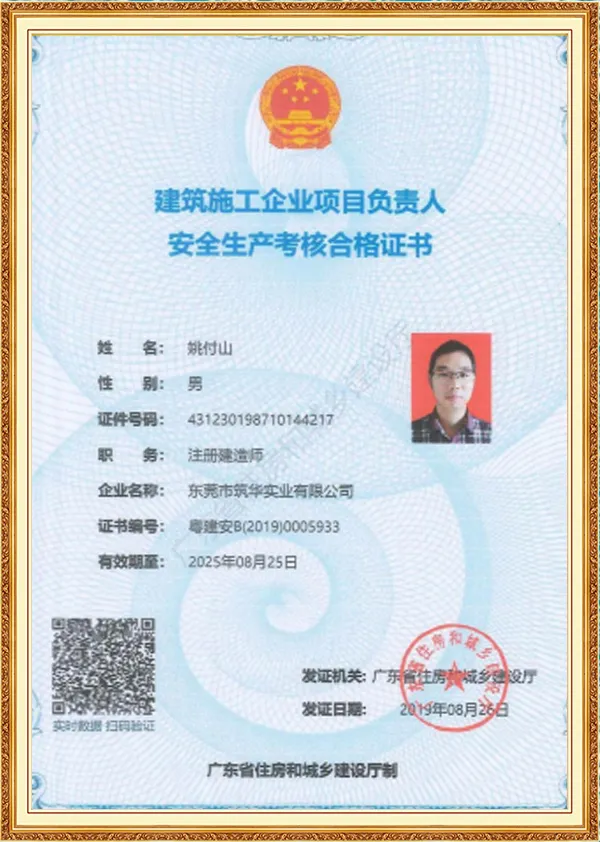

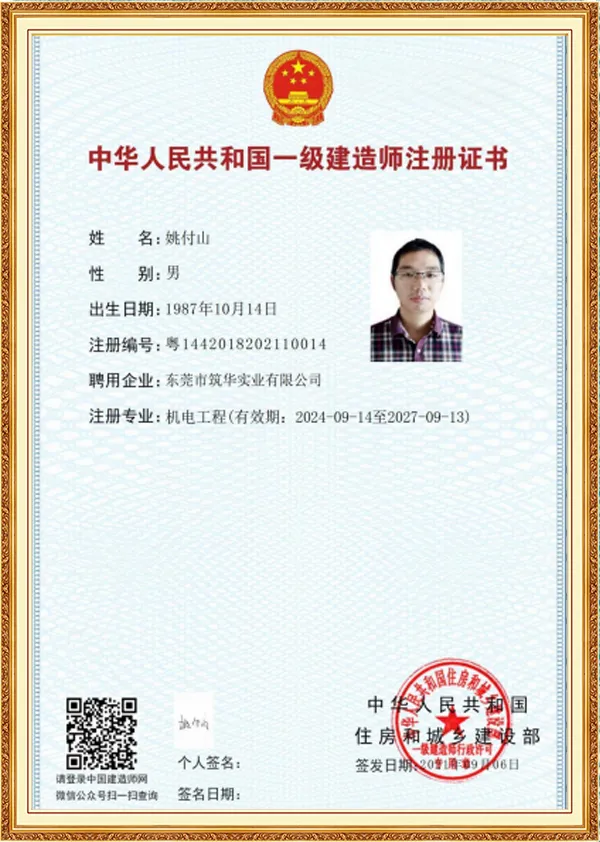

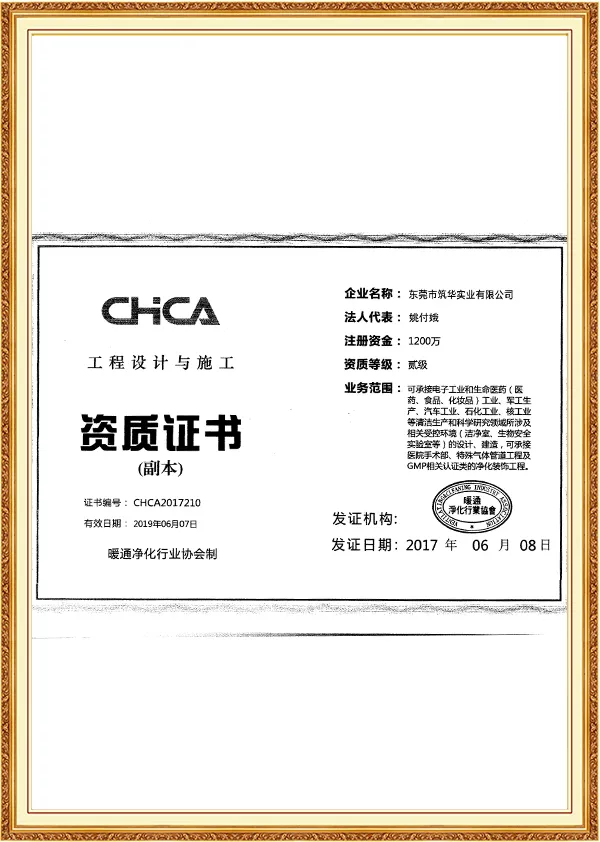

Certificate

Clients that Choose Us