- +86 135 6079 0959

+86 158 1435 8559 - zhuhuashiye@dgzhuhua.com.cn

CLEANROOM CLASSIFICATIONS

ISO14644-1 Cleanroom Classifications

| Cleanliness Class | The maximum concentration limit for particles with a particle size greater than or equal to the specified size(pc/m³) | |||||

| 0.1μm | 0.2μm | 0.3μm | 0.5μm | 1μm | 5μm | |

| 1 | 10 | 2 | - | - | - | - |

| 2 | 100 | 24 | 10 | 4 | - | - |

| 3 | 1000 | 237 | 102 | 35 | 8 | - |

| 4 | 10000 | 2370 | 1020 | 352 | 83 | - |

| 5 | 100000 | 23700 | 10200 | 3520 | 832 | 29 |

| 6 | 1000000 | 237000 | 102000 | 35200 | 8320 | 293 |

| 7 | - | - | - | 352000 | 83200 | 29300 |

| 8 | - | - | - | 3520000 | 832000 | 29300 |

| 9 | - | - | - | 35200000 | 8320000 | 293000 |

Cleanroom Design

Design Philosophy & Standards

Compliance: Aligned with international standards (ISO 14644, GMP etc.)

Customization: Tailored solutions for cleanliness classes ISO 3–9 (covering ultra-clean to basic clean environments).

Core Principles: Pressure difference and temperature difference control (to prevent contamination), Energy-efficient design (frequency conversion fans, heat recovery technology)

Key System Design Modules

1. Architectural Structural System Design

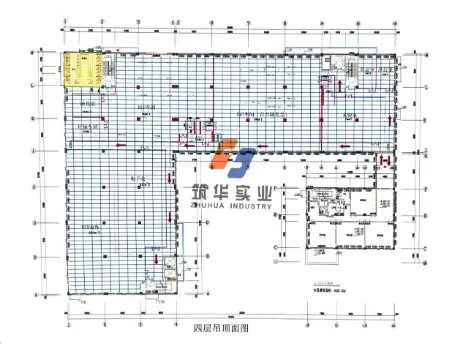

Ceiling System — Precision-Built Overhead Barrier

- Utilizes 50mm/75mm thick mechanized color steel plates (core materials: magnesium oxysulfate, glass magnesium, etc., fire rating ≥ B1).

- Surface anodized for anti-static and acid/alkali resistance.

- T-shaped aluminum alloy keel ensures ≥50kg/m² load capacity.

- Seams filled with two-component silicone sealant and sealed with aluminum alloy trim strips, achieving airtightness ≤0.5m³/(m²·h) (50Pa differential pressure test).

Core Advantages:

- Standardized equipment interfaces (FFU mounting holes with ±1mm precision) for modular installation.

- Customizable curved ceiling edges with integrated air supply plenum design for optimized airflow.

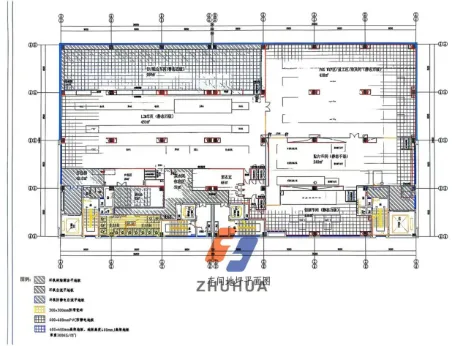

Flooring System — Multi-Solution Adaptability

A. Anti-Static Epoxy Self-Leveling Floor (ISO Class 5–8):

- Base layer precision: ≤2mm/3m flatness.

- Mid-layer: High-strength solvent-free epoxy mortar (quartz sand + resin, 1–2mm thickness). - Top layer: Pure solvent-free epoxy coating (0.5–1mm, R9 slip resistance, >500,000 forklift cycles).

- Seamless integration with 150mm curved skirting for hygiene compliance.

B. PVC Cleanroom Sheet Flooring (Pharma/Food Industries):

- 2–3mm homogeneous PVC sheets (CE-certified, ECO-1 compliant).

- Welded seams (≥8N/mm strength), nano-antibacterial coating (≤0.1 CFU/cm² bacterial passage), and chemical/thermal resistance (-20°C to 60°C).

Customization:

- Raised flooring for heavy-load zones with underfloor maintenance access.

- Lead plate shielding for radiation protection (optional in medical cleanrooms).

Wall System — Fully Sealed Low-Particle Interface

- 50mm color steel plates (double-sided zinc coating ≥120g/m²).

- R50mm curved aluminum transitions at corners, T-shaped trim strips at wall-floor/ceiling joints, and self-leveling sealant for "zero right-angle" design.

Technical Highlights:

- Embedded thermal-break aluminum doors/windows with double-laminated tempered glass (airtightness Class 8).

- Pre-welded stainless steel door frames for GMP-grade sterile docking.

- Customizable explosion-proof walls (blast resistance ≥0.1MPa).

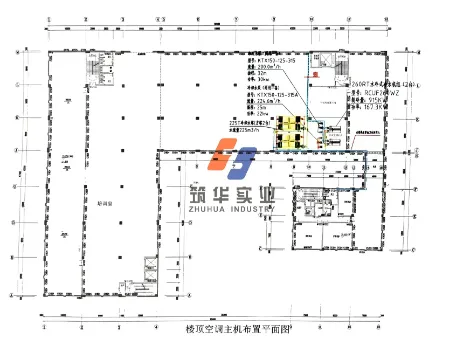

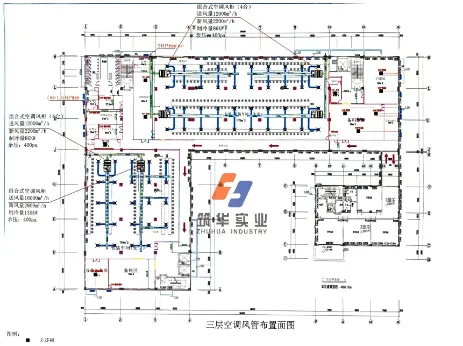

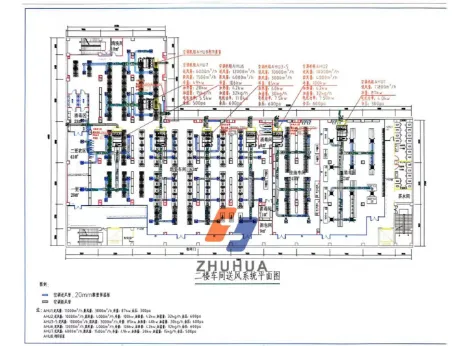

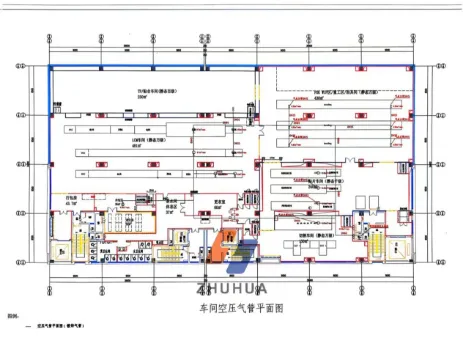

2. Air Handling System Design

HVAC Ductwork — Efficient Energy Transfer

- Galvanized steel/stainless steel ducts with flange/spiral seam connections (leakage below national standards).

- Smooth interiors, low resistance, and insulated for minimal thermal loss.

Air Supply/Return — Clean Airflow Circulation

- Multi-stage filtration (pre-filter, medium-efficiency, HEPA) for ≥99.99% efficiency on ≥0.5μm particles.

-Custom airflow patterns (top-supply/side-return,top-supply/bottom-return) with CFD-optimized layouts.

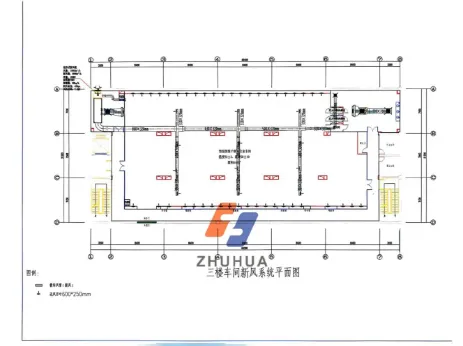

Fresh Air System — Controlled External Air Intake

- Dedicated AHU with pre-filtration, cooling/heating, and humidity control.

- Fresh air volume calculated based on occupancy and process needs.

Exhaust System — Contaminant Removal

- Corrosion/explosion-resistant fans and ducts for targeted pollutant extraction.

- Heat recovery integration to reduce energy consumption.

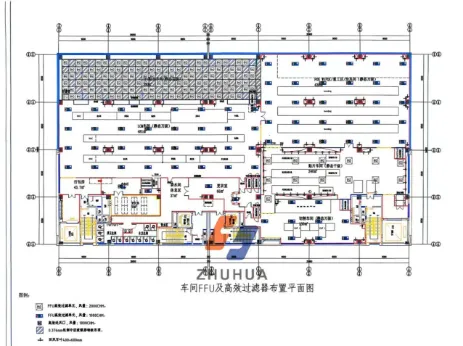

FFU Laminar Flow System — Localized ISO Class 5+ Zones

- Modular FFUs with HEPA filters and low-noise centrifugal fans for vertical unidirectional airflow.

HVAC Integration Benefits

- Smart Control: BAS for real-time parameter monitoring and automated adjustments.

- Energy Savings: 30%+ reduction via VFDs, heat recovery, and free cooling.

- Redundancy: Dual fans/cooling sources for uninterrupted operation.

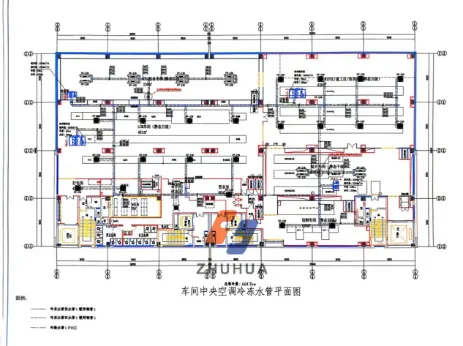

2. MEP Utility Systems

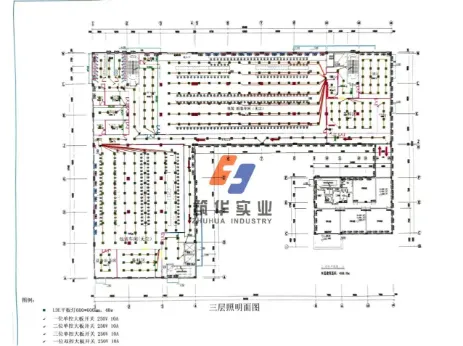

Cleanroom Lighting — Anti-Glare Solutions

- Embedded LED fixtures (PP/aluminum, UGR ≤19) with IP65 rating and optional smart dimming.

Power Distribution — Reliable Supply

- IP54+ cabinets with circuit protection and intelligent monitoring for fault detection.

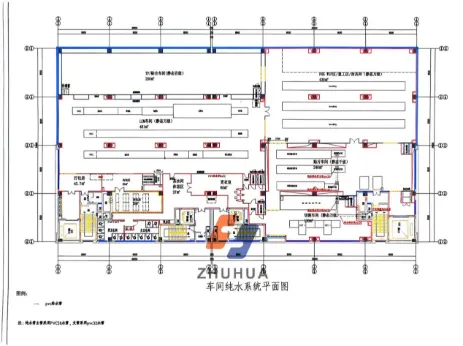

Piping Systems — Contamination-Free Transport

- 316L stainless steel for purified water, electropolished pipes for compressed air.

- Orbital welding, helium leak testing, and slope/drainage design.

Low-Voltage Systems — Intelligent Management

- Integrated CCTV, access control, environmental monitoring, and BAS for remote automation.

Utility Integration Benefits

- Unified Design: Cross-system compatibility and synergy.

- Energy Efficiency: 20%+ energy savings via smart controls.

- Ease of Maintenance: Modular components and real-time diagnostics.

FAQ

How to select a cleanroom HVAC system?

How to select a cleanroom HVAC system?

1. Filtration: Use HEPA (≥99.97% @0.3μm) for ISO 5–8; ULPA (≥99.9995% @0.12μm) for ISO 1–4.

2. FFUs (Fan Filter Units): Modular design for localized cleanliness upgrades, common in semiconductors.

3. Climate Control: Pharmaceuticals require 20–24°C/45–60%RH; semiconductors demand tighter control (e.g., 18±0.5°C).

How to handle microbial contamination in a cleanroom?

How to handle microbial contamination in a cleanroom?

1. Disinfection plan: Use hydrogen peroxide (VHP) and quaternary ammonium disinfectants, and rotate them regularly to avoid the development of drug - resistance.

2. Biosafety cabinet: It must comply with the ISO 14644 - 5 standard. Class II A2 is suitable for low - risk operations, and Class III is used for high - protection requirements.

3. Environmental monitoring: Conduct surface wiping (using the contact plate method) weekly and sample airborne microorganisms (using an Andersen sampler) monthly.

How to monitor the differential pressure and airborne particles in a cleanroom?

How to monitor the differential pressure and airborne particles in a cleanroom?

1. Monitoring points: Differential pressure gauges (with an accuracy of ±1Pa) should be installed between clean and non - clean areas and between clean areas of different classes. Airborne particle counters should be placed in clean areas.

2. Daily records: Record the differential pressure data and the number of airborne particles daily. Investigate the causes of abnormal fluctuations within 48 hours.

What if the microbial monitoring results are abnormal?

What if the microbial monitoring results are abnormal?

1. Incomplete disinfection and uncleaned dead corners in equipment.

2. Optimize the disinfection plan (e.g., extend the VHP exposure time).

3. Clean the interior of equipment and use an endoscope for inspection.

What if there are large fluctuations in temperature and humidity?

What if there are large fluctuations in temperature and humidity?

1. Malfunction of the air - conditioning system or failure of sensors.

2. Check the refrigeration/humidification equipment and calibrate the temperature and humidity probes.

3. Activate the backup system to reduce downtime.

What if the differential pressure is unstable?

What if the differential pressure is unstable?

1. Damper malfunction or insufficient fresh air volume.

2. Check the damper actuators and clean the air filters.

3. Adjust the ratio of fresh air to return air to ensure balanced air volume.